Last updated on March 18th, 2025 at 03:16 am

Corrugated roofing is famous for residential and commercial buildings due to its durability, versatility, and cost-effectiveness. Characterized by its distinctive wavy pattern, corrugated roofing provides excellent weather resistance and strength.

Table of Contents

It is available in various materials, each offering unique benefits for applications and environments.

Types of Corrugated Roofing Materials

- Metal Corrugated Roofing

- Plastic Corrugated Roofing

- Bitumen Corrugated Roofing

- Fiber Cement Corrugated Roofing

Metal Corrugated Roofing

Galvanized Steel

- Overview: Galvanized steel is coated with a zinc layer to protect against corrosion.

- Benefits: Durable, cost-effective, and resistant to rust and weather damage.

- Applications: Ideal for agricultural, industrial, and residential roofing.

Aluminum

- Overview: Lightweight and corrosion-resistant metal.

- Benefits: Long-lasting, energy-efficient, and low maintenance.

- Applications: Commonly used in coastal areas due to its resistance to saltwater.

Copper

- Overview: Premium metal is known for its distinctive appearance.

- Benefits: Extremely durable, develops a patina over time and has excellent thermal properties.

- Applications: High-end residential and commercial buildings.

Zinc

- Overview: A flexible and durable metal with self-healing properties.

- Benefits: Long lifespan, environmentally friendly, and low maintenance.

- Applications: Suitable for both contemporary and traditional architecture.

Stainless Steel

- Overview: Highly durable and resistant to corrosion.

- Benefits: Long-lasting, low maintenance, and aesthetically appealing.

- Applications: Used in both residential and industrial settings.

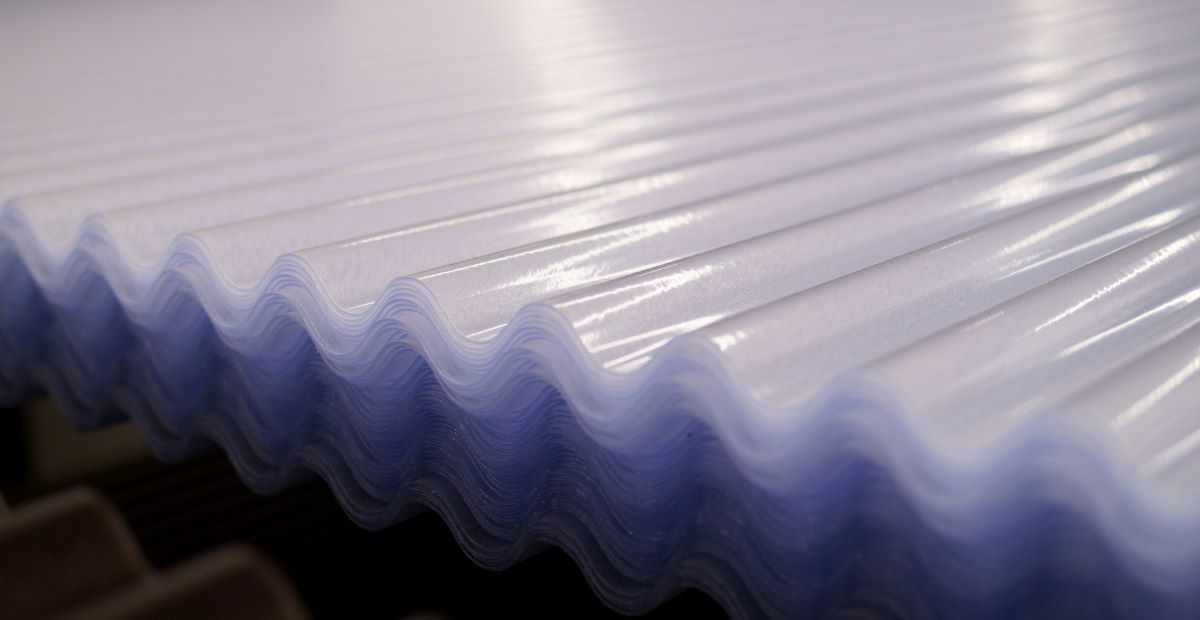

Plastic Corrugated Roofing

Polycarbonate

- Overview: A strong, transparent plastic material.

- Benefits: High impact resistance, UV protection, and lightweight.

- Applications: Greenhouses, patios, and skylights.

PVC (Polyvinyl Chloride)

- Overview: Versatile and cost-effective plastic material.

- Benefits: Resistant to chemicals, fire, and impact.

- Applications: Sheds, garages, and temporary structures.

Fiberglass Reinforced Plastic (FRP)

- Overview: Composite material made of a polymer matrix reinforced with fibers.

- Benefits: Durable, lightweight, and resistant to corrosion and UV rays.

- Applications: Industrial buildings, warehouses, and agricultural structures.

Bitumen Corrugated Roofing

Corrugated Bitumen Sheets

- Overview: Made from bitumen-soaked fibers and resins.

- Benefits: Waterproof, soundproof, and lightweight.

- Applications: Garden sheds, garages, and agricultural buildings.

Asphalt Roofing

- Overview: Made from asphalt-coated fiberglass or organic felt.

- Benefits: Affordable, easy to install, and available in various colors.

- Applications: Residential homes and low-slope roofs.

Fiber Cement Corrugated Roofing

Composition and Benefits

- Overview: Made from cement reinforced with cellulose fibers.

- Benefits: Fire-resistant, durable, and low maintenance.

Applications

- Overview: Suitable for residential, commercial, and industrial buildings.

- Benefits: Versatile and aesthetically pleasing, suitable for modern and traditional designs.

Comparison of Different Corrugated Roofing Materials

Durability

- Metal Roofing is extremely durable, with a lifespan of 50+ years. It is resistant to rust (especially galvanized steel, aluminum, and stainless steel) and can withstand harsh weather conditions.

- Plastic Roofing: Moderately durable. Polycarbonate and FRP are more impact-resistant, while PVC has lower impact resistance.

- Bitumen Roofing: Fairly durable with a lifespan of 20-30 years, but less resistant to extreme weather compared to metal.

- Fiber Cement Roofing: Highly durable, fire-resistant, and long-lasting, with a lifespan of 30-50 years.

Cost

- Metal Roofing: Generally more expensive upfront but offers long-term savings due to durability and low maintenance.

- Plastic Roofing: Affordable and cost-effective, with variations depending on the type of plastic.

- Bitumen Roofing: This is a low-cost option, making it an economical choice for many applications.

- Fiber Cement Roofing: Mid-range cost, providing a good balance between affordability and durability.

Weight

- Metal Roofing: Lightweight, which reduces the structural load on buildings and simplifies installation.

- Plastic Roofing: Very lightweight, making it easy to handle and install.

- Bitumen Roofing: Lightweight but varies depending on the specific product.

- Fiber Cement Roofing: Heavier than metal and plastic but still manageable for most structures.

Installation Process

- Metal Roofing requires precise installation, often requiring professional expertise. Installation involves cutting, fastening, and sealing.

- Plastic Roofing: Easy to install, often as a DIY project. Sheets are lightweight and straightforward to cut and fasten.

- Bitumen Roofing: Simple installation process, often nailed or screwed into place. Suitable for DIY.

- Fiber Cement Roofing: Requires careful handling due to its weight and brittleness. Professional installation is recommended.

Aesthetic Appeal

- Metal Roofing offers a sleek, modern look with various finishes and colors. It can suit both contemporary and traditional styles.

- Plastic Roofing: Available in transparent and opaque options, suitable for creating bright and airy spaces.

- Bitumen Roofing: Typically available in darker colors and provides a rustic, traditional appearance.

- Fiber Cement Roofing offers a natural, textured look. It is available in various colors and styles to match different architectural designs.

This comparison highlights the key attributes of each corrugated roofing material, helping you make an informed decision based on your specific needs and priorities.

Factors to Consider When Choosing Corrugated Roofing Materials

Climate and Weather Conditions

- Consideration: Choose materials that withstand local weather patterns.

- Details: Metal roofing is ideal for extreme weather, while aluminum is perfect for coastal areas. Bitumen performs well in wet climates; fiber cement is excellent for fire-prone areas.

Building Structure and Design

- Consideration: Match roofing material with the building’s structural capabilities and architectural style.

- Details: Lightweight plastic suits simple structures, whereas heavier fiber cement requires more substantial support. Metal roofing offers versatile design options.

Budget Constraints

- Consideration: Balance between initial costs and long-term value.

- Details: Metal and fiber cement have higher upfront costs but offer longevity and low maintenance. Plastic and bitumen are more affordable initially but may incur higher long-term maintenance costs.

Maintenance Requirements

- Consideration: Factor in the ease and frequency of maintenance.

- Details: Metal and fiber cement require minimal maintenance. Plastic may need more frequent cleaning and repairs, and bitumen can require periodic replacement or repair.

Longevity and Warranty

- Consideration: Assess the expected lifespan and warranty of the roofing material.

- Details: Metal and fiber cement offer the most extended lifespans, often with extensive warranties. Plastic and bitumen have shorter lifespans and limited warranties.

Conclusion

Choosing the suitable corrugated roofing material involves balancing durability, cost, and maintenance needs against your specific environmental and structural conditions. Metal and fiber cement are ideal for long-term, low-maintenance solutions, while plastic and bitumen provide more affordable, accessible options for various applications.

Contact us today to schedule your roofing repair or installation project and experience the Pally Roofing difference.

Author

-

With more than 16 years of hands-on experience, Phillip Schmucker is the knowledgeable owner of Pally Roofing. His dedication to superior roofing services has earned him a reputable place in the industry. Phillip also shares his extensive expertise through writing, providing readers with practical tips and professional advice on various roofing topics. Follow him on LinkedIn.

View all posts