Last updated on January 7th, 2025 at 05:44 pm

“Torch-down roofing” is frequently used in commercial roofing, mainly when discussing flat or low-slope roofs. But what precisely is it, and why should it matter to you? We’ll examine the specifics of torch-down roofing in this post, including its components, advantages, disadvantages, and many more.

Table of Contents

A Torch-Down Roof: What Is It?

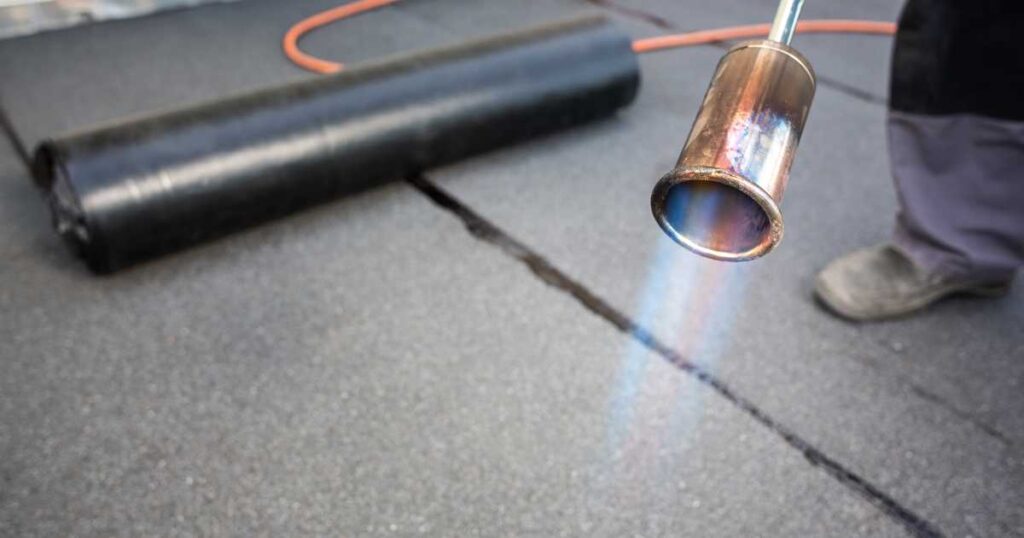

Torch-down roofing, called “torch on” roofing, gets its name because it needs an open-flame propane torch. With this installation technique, modified bitumen sheets are rolled out onto the roof, and the material is heated and adhered to the surface by a roofing specialist using a hand-held propane torch. Seams are fused to create a waterproof seal once the layers reach the proper temperature.

A torch-down roof’s membrane layers comprise bitumen, an asphaltic substance altered with plastic or rubber. This type of roofing’s primary advantage is its ability to stretch and shrink without melting or cracking. It can withstand extremes of heat and cold that it will encounter on the roof as the seasons change. Torch-down roofing comes in two- and three-layer systems, among other varieties.

A Torch-Down Roofing: Material

A torch-down roof may have been referred to as a “rubberoid” roof, which suggests the material comprises rubber, but the term may not be precise. Bitumen with additives, or modified bitumen, is used to make all torch-down roofing. Bitumen is derived from asphalt, a durable substance utilized in numerous roofing conditions. Bitumen must be changed or mixed with a polymer to manufacture torch-down roofing. Torch-down roofing material comprises several membranes that are layered and bonded together to form each sheet. From bottom to top, these are the torch-down roofing material’s membrane layers:

- Layer 1: Thermo-fusible film

- Layer 2: Modified bitumen

- Layer 3: Reinforced Polyester

- Layer 4: Modified bitumen

- Layer 5: Granulated minerals surface

Torch-Down Roofing: Application

- Insulation:Insulation is necessary for a flat or low-slope roof to retain heat within a building or structure, especially in colder climates. Depending on the kind of deck and the performance level that the designer has set, the insulation is installed first. Either all of it is glued on or heated mopped on, or it is fastened manually with screws and plates.

- Vapor barrier:The vapor barrier comes next. This underlayment aids in preventing moisture buildup and condensation on the roof.

- Overlay board:To support the torch-down roofing membrane, the roofing expert will install an overlay board, also known as a cover board. Correct overlay board application is necessary to avoid “ponding,” which occurs when an imbalanced roof collects water.

- Base sheet:The modified bitumen membrane’s initial layer is this one. The base sheet can be adhered to the overlay board for torch-down roofing via glue, hot mopping, or direct heat fusion.

- Smooth cap sheet: this is the upper membrane sheet of a torch-down roofing system. The roofing expert will heat the base sheet from the top to the bottom of the cap as it is rolled out using a torch. The two layers create a seal when they are forced together. This completes the system in a two-layer torch-down roof. If not, the same method is used to apply a third layer that contains granules.

- Install Flashing: Self-adhering modified bitumen membranes flash around elements that pierce the roof, such as vents or HVAC (heating and air conditioning) units. Metal flashing is applied above that. The metal is prepared before the base sheet attachment to help in adherence.

Torch Down Roofing: Maintenance

Maintaining your torch down the roof will help to extend its life. Over time, you must inspect, clean, and repair it regularly. To extend the life of your roof, you should:

- Checking your roof twice or three times a year, as well as following severe storms

- Clearing debris using a leaf blower or broom

- Coating update every three to five years

- Patching raised seams, cracks, and holes

- Gutter and drain cleaning

Torch Down Roofing: Cost

Materials and installation for torch-down roofing typically run between $3 and $7 per square foot. However, if high-quality materials are utilized or installation can be made more accessible, the cost can increase. For example, the price might be higher if a roof requires additional insulation, repairs, or removing outdated roofing materials. Furthermore, the cost of some materials may be higher than regular, modified bitumen, such as TPO or PVC. Lastly, it’s critical to remember that the cost of torch-down roofing must account for labor costs.

Torch-Down Roofing: Advantages

- Lifespan

One of the critical features of a torch-down roof is its 15–20-year longevity. The lifespan of torch-down roofing is longer than that of certain other kinds of flat roof systems. This is because of its resilience to water damage and flexibility in hot and cold climates.

- Energy Efficiency

Torch-down roofing offers protection from heat and UV radiation, particularly when combined with a cap layer in three-layer roofing. In warmer weather, the surface of your torch down the roof can help reduce your cooling costs.

- Water Resistance

Any roof’s primary function is to prevent water from entering the structure below. It is significantly more challenging to complete this task on flat roofs. This is especially true in areas where snow accumulation on the roof can result in a considerable delay in melting. One of the best flat roof systems for water resistance is torch-down roofing, which features heat-sealed joints and extremely waterproof membranes. Torch-down roofing encourages drainage and keeps water from building up and pooling on the roof when appropriately put by an expert. Additionally suitable for protecting buildings from snow accumulation damage is torch-down roofing.

- Less Dangerous Emissions

The fumes might be a factor when choosing between a torch-down and mop-on roof coating. Although torch-down roofing still has some disagreeable odors, it releases much less dangerous gases than asphalt roofing. Your roofer may need to take additional breaks when using a mop on roofing to make sure they aren’t breathing in too much.

- Easy Repair

Finally, torch-on roofing is straightforward to fix compared to other roofing materials. Compared to repairing various roofs, the method is less time-consuming and costly because it rolls on and seals rapidly.

Torch-Down Roofing: Disadvantage

- Fire Hazard

The main drawback of torch-down roofing is that it is installed over an open flame, which means there is always a fire risk. Modified bitumen is a very fire-resistant building material. However, the compound may degrade and catch fire if it overheats during installation. Applying a torch down the roof can be dangerous because it can burn nearby flammable items like dry plants or a house’s wood frame. These issues will be carefully examined and fixed before a torch-down roof is installed when you engage with a qualified, insured, and experienced roofing contractor. Working with a roofing professional considerably reduces the risk of the process.

- Seams Failure

Roof leaks may occur if the joints of the burned-down roofing material don’t seal. Although less often, this can still happen with a three-layer roof. Sealing the roofing seam can be done quickly and simply if this occurs.

- Not Rip-And-Scratch-Resistant

Despite its extreme flexibility and durability, a torch-down roof is at risk of tearing and scratching. The performance of a torch-down roof depends on its watertight seal, which is damaged or ripped and compromises the roof system. This can be prevented by performing routine roof maintenance, inspections, and little repairs as needed.

- Trapped Water

During installation or maintenance, water can become trapped between the layers of rolled roofing. Torch-on roofing should only be installed or repaired in dry weather.

- Drawbacks Of A Flat Roof

Since the torch on roofing is a flat roof system, it must be highly robust and water-resistant. Even with the most muscular flat roof system, you must regularly maintain and check your flat roof. Flat roofs are more likely to accumulate garbage and develop areas where water collects, and snow builds up. To ensure your flat roof is sturdy enough to endure everyday wear and tear and torch-down roof application, have it evaluated by a competent roofing contractor.

Torch-Down Roofing: Right For You?

A torch-down roof system performs best when flexibility and water resistance are your main concerns for gently pitched roofs. Intense weather conditions, including extremes in temperature, persistent rain, and even snow accumulation, are no match for torch-down roofing. You cannot put a torch down roofing on your own; instead, it needs to be done by a roofing specialist. However, torch down might be an excellent alternative for your flat roof if you want a roof that is long-lasting, extremely durable, and simple to repair.

Our knowledgeable roofing crew is prepared to handle any roof installation or repair at Pally Roofing. We have installed torch-down roofing before. You can rely on us as your preferred roofer. Get the most recent updates by giving us a call or visiting our page.

FAQs

How good is torch-down roofing?

One of the numerous benefits of torch-down roofing is that it is weatherproof and performs well in all weather conditions, including intense heat and snowfall. For roofs with a slight pitch, torch-down roofing works well. Since modified bitumen membrane patches must be burned to the gaps, repairing a torch-down roof is very easy.

What kind of roofing material works best for torch downs?

Bitumen combined with a polymer to create modified bitumen makes all torch-down roofing. Bitumen changed with Styrene Butadiene Styrene (SBS), and Atactic Polypropylene (APP) are examples of distinct polymers. Both are flexible, but bitumen treated with SBS has a lower melting point and may be applied with a torch.

Which is preferable to torch-down roofing: TPO or EPDM?

Regarding insulation and resistance to snow and rain, TPO roofing is better than EPDM roofing. It also features reduced sunlight reflection and improved water resistance. TPO roofing can be placed over a burned-out roof with no modification, making it an excellent option for people seeking a sleek and contemporary look.

What is the minimum slope needed to install torch-down roofing?

Although roofs with a slope of up to 3:12 can be installed as a torch-down roof, a hill of 1/2:12 or less is ideal.

Is roofing waterproof when using a torch?

Roofs with torch downs are waterproof. When placed on a sturdy roof deck, they have a waterproof membrane.

Can a torch-down roof be put on top of an existing roof?

Yes, but only after the old roof needs to be prepared. Speak to an expert if you intend to put over an existing roof. Although it will only last for a while, many roofers advise against replacing an old roof with a new one, even though doing so can save homeowners money and time.

Author

-

With more than 16 years of hands-on experience, Phillip Schmucker is the knowledgeable owner of Pally Roofing. His dedication to superior roofing services has earned him a reputable place in the industry. Phillip also shares his extensive expertise through writing, providing readers with practical tips and professional advice on various roofing topics. Follow him on LinkedIn.

View all posts